dxw’s Introduction to Kanban Workshop

Introduction to Kanban Workshop

Last week, I attended dxw’s “Introduction to Kanban” workshop as part of my internship to learn about the revolutionary workflow management technique spearheaded by Toyota. “Kanban” in our context is an agile development method that allows development teams more control over the production of their product.

Workshop Aims

Aiming to introduce those present to the concept of limiting your work in progress, the workshop was our guide to running a successful kanban initiative through the use of a kanban board.

By delving into the history of the kanban methodology and using it to make ‘pizza’ we were taught how to make our workflow more efficient.

You’ve got to start somewhere…

We kicked off the workshop with a brief lesson on what Kanban means and how it came to be. Firstly, the Kanban system originated in the 1940s within Toyota as a way to improve manufacturing efficiency and reducing waste. When you translate Kanban into English it’s literal meaning is ‘a sign’ and it is this that provides the best way of describing kanban; a visual representation of workflow.

Delivery Manager Alex Jackson then walked us through the main principles of kanban:

- Start with what you do now

- Place an emphasis on value in the system

- Visualise the workflow

- Limit your work in progress (WIP)

- Agree to pursue incremental, evolutionary change

- Respect the current process

- Encourage acts of leadership at all levels

- Use feedback loops

Importantly, these are principles, not rules or guidelines. The kanban method does not prescribe to any pre-written rulebook but instead stimulates organic improvement that is continuous and incremental.

Cracking the WIP and making “pizza”

Kanban has since migrated from Toyota to other industries and to other countries, where it is used to visualise change management and service delivery workflows. At dxw, this method of working allows our teams to visualise their projects from start to finish, to track their work and keep team members up to speed on where they are. Ultimately it allows whole teams to collaborate by creating an easily accessible visualisation of where they currently reside within the workflow.

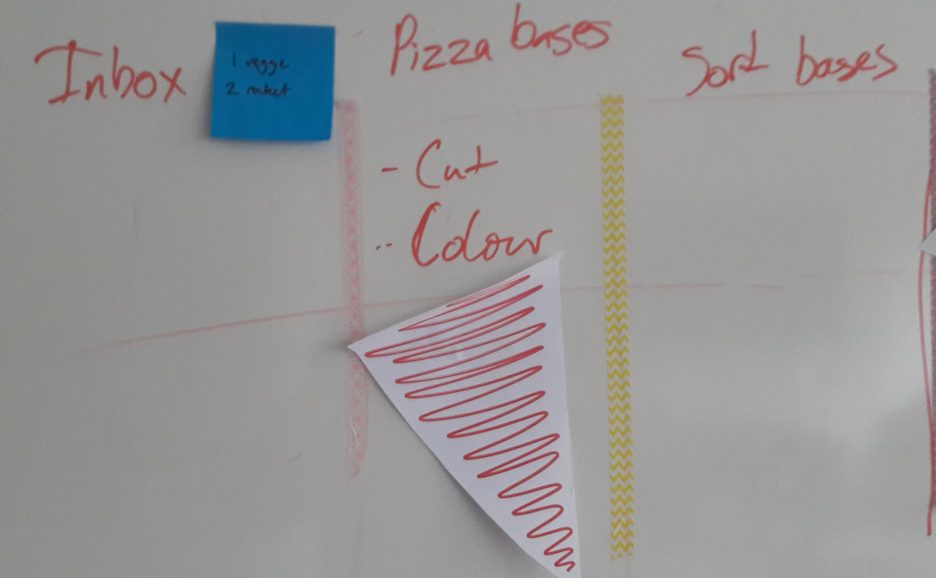

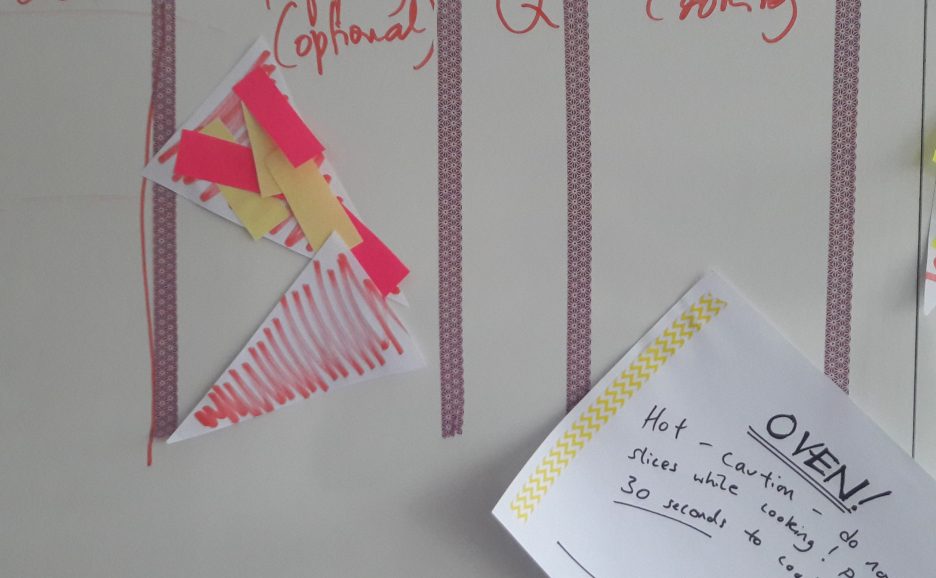

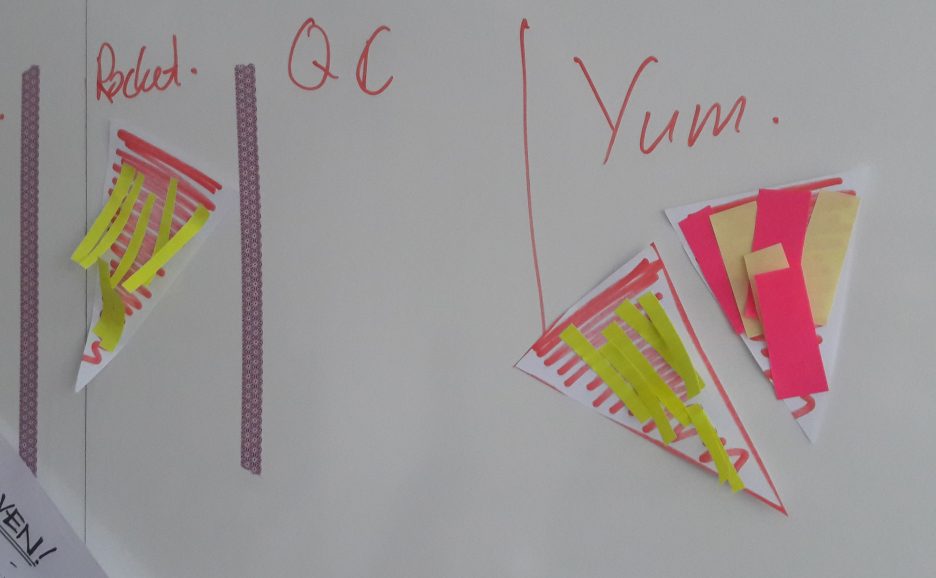

During the workshop we played the ‘Pizza game’ which is designed to illustrate the importance of limiting work in progress. By doing this, we were able to experience how agile methodology can emerge from an existing system whilst adapting our workflows. By physically producing ‘pizza, the workflow becomes easier to visualise and understand how the production can be improved.

By making ‘pizza’ in rounds with only limited information, each person was able to understand the context of their own work and how it impacted the team as a whole. So, by introducing limits on our work in progress throughout the rounds we were able to identify how our behaviour changed when limits were put on our ability to progress with work.

One main strength of implementing the Kanban system is that it does not simply abandon any work done up to that date. Instead it starts by mapping out the existing work processes and allows you to find any blockers that may have been present in order to improve the flow of work.

Summary

A dxw “Introduction to Kanban” workshop is a great way for people to learn how to implement clearer and more organised workflows and adapt them to their current projects. By opening up the way dxw works to people from other organisations, we can share our knowledge with people to have some impact on the way change management and service design is delivered within the public sector.

At dxw, we believe that being open about our work benefits all of those involved and establishes an honest and collaborative working environment. Collaborative methods form collaborative teams that ultimately enjoy creating the best product possible whilst getting the most done and shipped.